The Construction Process

-

Phase 1

Concept Development

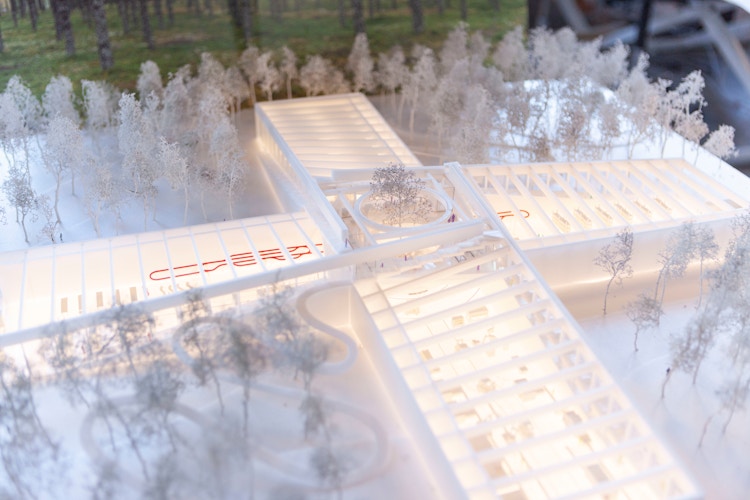

The journey starts in the autumn of 2019. Vestre and the architectural firm BIG find themselves on the same wavelength straight away, and together with skilled advisers, their quest for the perfect site begins. The Kongsvinger region is the most relevant because it is close to Vestre’s existing factory in Torsby, Sweden. Over 20 different locations are considered. In a few months, the concept of The Plus is created.

-

Phase 2

Design

Design of The Plus continues throughout the spring of 2020. More than 30 architects, landscape architects, designers, engineers, building physicists, biologists, ecologists and technologists – from more than 15 countries and 3 continents – contribute to the design. Teamwork across disciplines, experience, cultures and national borders is the key to achieving revolutionary results.

-

Phase 3

Launch

The Plus is launched at a live event at Vippa in Oslo on 30 June 2020. You can see the entire launch here. In a matter of days and weeks, The Plus becomes a talking point in more than 30 countries, and in renowned magazines such as Wallpaper, Forbes and Fast Company.

-

Phase 4

Site Preparation

In September 2020, preparation of the construction site begins. We are keeping the planted pine forest as close to the building and the roads as we possibly can, and all the timber from the trees that were felled will be used in The Plus as building materials. The technical infrastructure, such as power, fibre, water and sewerage, is being installed along the roads to keep encroachment on nature to a minimum. The forest floor will be set aside with great care, to preserve the seed bank. This will be reused on the building’s green roofs and in the surrounding areas.

-

Phase 5

Earthworks

In early 2021, Magnor is in the grip of a cold winter. Temperatures down to minus 25 degrees C present challenges for casting foundations with low-carbon concrete, and the fossil-free construction machines also develop problems. Thanks to plenty of creativity and perseverance, the project is only delayed by 2 weeks. The foundations of The Plus have been customized to meet the project’s extreme requirements in terms of building physics. To keep emissions low, 100% recycled reinforcement steel is used.

-

Phase 6

Timber Structure

On Monday 22 February, the first wall of solid wood is hoisted into place. In the following weeks, the first factory wing – the Vestre Colour Factory – takes shape in record time, and with millimetre precision. The glulam beams have a free span of 24 metres. They are 1.8 metres high and each beam weighs up to 5 tonnes. The timber structure is a Norwegian-Swedish partnership between Woodcon in Brumunddal, Moelven outside Lillehammer and Stora Enso in Värmland.

-

Phase 7

Cladding

The first immigrants to Norway came from Finland in the 17th century. They settled in a forested area along the Swedish border in Hedmark. The area came to be known as Finnskogen, which includes the town of Magnor. They brought swidden agriculture with them. This shifting cultivation method involves clearing and burning areas of land, which then become fertile soil for growing rye. To showcase this proud tradition, the building’s façade material is charred larch timber cladding, in harmony with the old-growth trees around the factory. Work on the cladding starts in the summer of 2021.

-

Phase 8

Glass Façades

The Plus aims to reduce the need for delivered energy by at least 90% compared to an equivalent factory building. With more than 2000 square metres of glass façades – up to 14 metres high – there are extreme requirements for energy performance, insulation, thermal bridges and building physics in general. The glass façades have been specially developed for the Plus to ensure the maximum transparency and the lowest possible energy consumption. In the profiles that frame the glass, we are using Hydro CIRCAL, the greenest aluminium in the world. This material consists of at least 75% recycled post-consumer scrap from soda cans, car parts and all kinds of other things. Installation of the glass façades takes place from June onwards.

-

Phase 9

Green Roofs and Solar Panels

The main aim of The Plus is to showcase how it is possible to unify industry, climate and nature. One of many expressions for this is the roof of the factory. Not only is it open and accessible to the public all the time. It also consists of around 1,000 high-efficiency solar panels surrounded by green vegetation. Over 20,000 plug plants will be planted on the roof, based on biological material collected from the surroundings. In this way, the natural vegetation of the area will take over the factory roof in a few years. In addition, there will be plants for pollinating insects. The work on green roofs and solar panels will start in the autumn of 2021.

-

Phase 10

Stairs and Slide

From September 2021 onwards, the external staircases will be installed. Visitors have access to the factory roof via what we call 'donkey stairs' – stairs along the façades in Vestre Colour Factory and Vestre Wood Factory. It is also possible to get all the way up by taking the 'monkey trail': a 250-metre walkway that winds through the pine trees. When you are on the roof, you can take the 'courtyard stairs' down to the visitors’ centre and further down into the factory, where you have a 360-degree view of all the production wings. If you are in a hurry, a slide from the roof is ready for you. It will whisk you 14 metres down to the ground in a few seconds.

-

Phase 11

Technical installations

From a distance, The Plus may look like a beautiful cultural building. As you approach the large glass façades, a state-of-the-art furniture factory is revealed on the inside. Our aim is that nature, the architecture and the machines will play the lead roles in this narrative. This means that all the technical infrastructure – such as air handling units, chip and dust extraction, ventilation ducts, cables and conduits – is concealed in the building’s service corridors and in a network of culverts under the factory floors. Kilometres of invisible pathways have been included to provide an optimal experience for the public. Work on technical installations will continue right up to the completion of the building in December 2021.

-

Phase 12

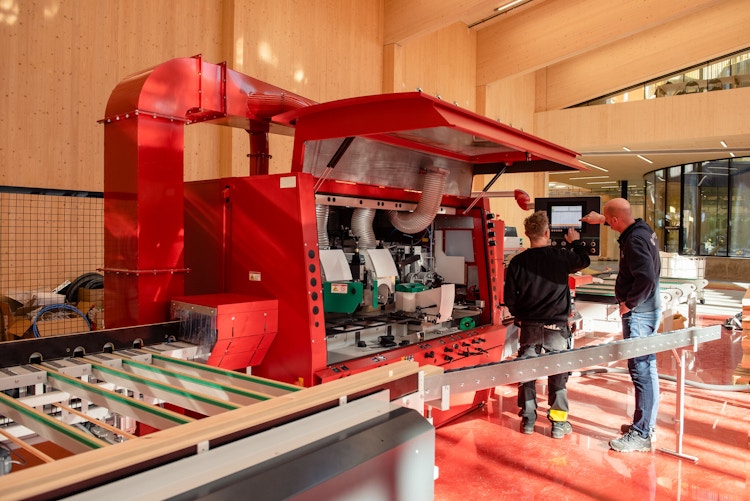

Machines

From August 2021, the installation of machinery will begin. The Plus uses pioneering Industry 4.0 technology such as self-learning robots, object recognition, laser cameras and virtual reality. Vestre Colour Factory will coat products faster and in a more environmentally friendly way than the Tesla factory in California. And while we are in the world of cars: Vestre Wood Factory would have impressed Henry Ford himself. Here, raw materials are fed into one end of the automated production line, and on the other side finished furniture components emerge at a breathtaking pace. Artificial intelligence enables optimal use of resources. In this way, Vestre will prove that we can compete worldwide from a high-cost country such as Norway.

-

Phase 13

Floor design

Each machine in The Plus has its unique colour. This colour is transferred to the floor around the machine and continues in a metro-like network of coloured lines to the centre of the factory. Children and adults can understand the production process by following the colours from machine to machine. Realization of the floor design starts in October 2021.

-

Phase 14

Landscape

The Plus aims to have the smallest footprint and environmental impact possible. The extent of construction roads and parking areas has been reduced to an absolute minimum throughout the construction process. When the construction equipment leaves, the forest floor will be restored to its original condition so that the natural landscape can develop freely all the way up to the façades. Forest paths will be developed between existing trees using natural materials. To prevent light pollution, smart sensors control the lighting. Landscaping takes place throughout the construction process.

-

Fase 15

Adventure Park

The Plus is not just a factory to experience. We will also build a 30-hectare (74 acre) park for the public, with playgrounds, art, culture, furniture and other adventures for people of all ages. Work starts in the autumn of 2021 and will continue for several years.

-

Phase 16

Takeover of Factory

On March 17, 2022, we took over the keys to the world's most sustainable furniture factory. It was our CEO Stefan Tjust, together with Vestre's co-owner Elisabeth Preus Vestre, who signed the takeover protocol for the factory. Here together with project manager Jan Myrlund from Fokus Rådgivning AS (far right).

-

Phase 17

The Plus

Vestre Color & Wood Factory

Floor space

7,000 m2Workforce

30-70 full-time equivalentsBudget

NOK 300 millionScheduled completion

2021/2022Construction owner

The Plus AS (Vestre)Architect / landscape architect / structural engineer

Bjarke Ingels Group (BIG)Project manager

Fokus Rådgivning ASMain contractor

Ø.M. Fjeld ASCLT and glulam

Woodcon AS

BREEAM-AP

Nordic Office of Architecture ASEcology

Asplan Viak ASRIV

Erichsen & Horgen ASRIE

Foyn Consult ASBuilding physics

Norconsult ASGeotechnics

Multiconsult ASSupported by

Innovation Norway, Enova, Eidskog Municipal Council, Klosser Innovasjon and SivaFinansiering

Danske Bank, Eksfin (GIEK)